What Language Is: Partnumberranges In Kaiserslautern – Explained!

Discovering Partnumberranges in Kaiserslautern was an eye-opener! It offered me a unique glimpse into structured systems, blending technical precision with practical problem-solving. This experience expanded my skills and deepened my appreciation for process optimization in real-world settings.

“Partnumberranges” in Kaiserslautern focuses on organizing technical components through systematic numbering. This method enhances precision and efficiency across various industries. Kaiserslautern’s innovative setting makes it ideal for exploring its practical applications.

Stay tuned as we dive deeper into What Language Is: Partnumberranges in Kaiserslautern! We’ll explore its fascinating concepts, practical applications, and how it transforms technical processes. You won’t want to miss this insightful journey!

What is PartNumberRanges – How It Revolutionizes Manufacturing!

In easy terms, PartNumberRanges refers to categorizing and organizing component numbers inside a described variety in a database or stock system. A component range is a unique identifier assigned to a selected thing or product, making it smooth to track, retrieve, and manipulate in the course of the producing technique or inside a bigger delivery chain network.

PartNumberRanges helps manufacturers and businesses group parts based on characteristics such as type, size, or function. By organizing parts into ranges, companies can avoid confusion, improve workflow, and reduce human error.

For instance, a range could look like this:

- Part numbers 1000-1999 could represent a specific category of bolts.

- Part numbers 2000-2999 might represent a different category, such as engine components.

This method of categorization streamlines operations simplifies inventory management, and enhances tracking, ensuring that the right parts are available at the right time.

Is PartNumberRanges a Programming Language – What You Need to Know!

A common misconception surrounding PartNumberRanges is that it might be a specific programming language used to manage parts in databases or ERP systems. However, the truth is that PartNumberRanges is not a standalone programming language. Rather, it is a concept or method used within various programming languages and software tools to manage part numbers and their ranges in manufacturing and supply chain systems.

Let’s break down the technologies that incorporate PartNumberRanges:

- SQL (Structured Query Language):One of the maximum extensively used languages to question and control databases. In the context of PartNumberRanges, SQL facilitates producers seek and retrieve element numbers from a database primarily based totally on unique ranges, which includes element numbers among one thousand and 1999 for bolts.

- Python and JavaScript: These programming languages are often used in the backend of inventory management systems and ERP applications. Python, with its data manipulation capabilities, is especially useful for working with complex part number ranges, automating part assignments, and processing large datasets.

JavaScript can be used for frontend applications to visualize part ranges or allow users to filter parts in real time.

- Enterprise Resource Planning (ERP) Systems: Systems like SAP, Oracle, and Microsoft Dynamics are commonly used in manufacturing and production environments to manage resources, production schedules, and inventory.

These systems include specific programming environments and tools for handling PartNumberRanges effectively.

In short, while PartNumberRanges is not a language, it is an essential methodology used across various software tools and languages.

Applications of PartNumberRanges in Kaiserslautern’s Industrial Sector:

Kaiserslautern, a city renowned for its automotive manufacturing and technology industries, is home to numerous businesses that rely on efficient production and inventory management. Here, PartNumberRanges plays a crucial role in organizing and categorizing parts across various industries.

Manufacturing & Production Systems:

In sectors like automotive manufacturing, engineering, and electronics, parts are produced in high volumes and must be precisely managed. Here, PartNumberRanges serve to:

- Categorize parts based on type, size, or purpose (e.g., parts numbered 1000-1999 for bolts, 2000-2999 for engine components).

- Streamline production lines by ensuring that each part can be quickly located and retrieved.

- Prevent production delays by reducing the likelihood of mismatches or errors when locating parts.

For example, a Kaiserslautern-based automotive factory might use PartNumberRanges to track engine components within a specified range. By assigning parts numbers in organized ranges, the factory can reduce errors, increase the speed of assembly, and improve overall productivity.

Inventory Management:

Efficient inventory management is a cornerstone of successful manufacturing. PartNumberRanges make inventory tracking far more straightforward by allowing businesses to:

- Group similar parts together based on their ranges, making it easier to track stock levels.

- Monitor inventory levels in real time, helping businesses avoid stockouts or overstocking.

In Kaiserslautern, industries like automotive manufacturing rely on accurate inventory systems to ensure the right parts are available at all stages of production. This minimizes downtime and allows for better resource management.

Supply Chain Management:

The use of PartNumberRanges also extends to supply chain management, where parts are tracked as they move through various stages of the production process. With PartNumberRanges, manufacturers can:

- Track parts in transit to prevent losses or misplacements.

- Identify issues in the supply chain and address them quickly by pinpointing part shortages or surpluses.

By effectively managing these ranges, manufacturers in Kaiserslautern can optimize their supply chain and reduce inefficiencies that may arise due to misplaced or untracked parts.

Read: Developsearcher.Site – Experience Seamless Development!

Technical Side of PartNumberRanges – How It Works?

Database Structuring for PartNumberRanges:

In manufacturing and inventory systems, PartNumberRanges are typically stored in relational databases designed for efficiency. These systems organize data into tables where part numbers are assigned to specific ranges.

The database is often structured with indexing to enable fast access and quick retrieval of part numbers that fall within a specified range. This structure is essential for handling large inventories, allowing systems to perform quick queries when parts need to be located or categorized.

Automation through Backend Logic:

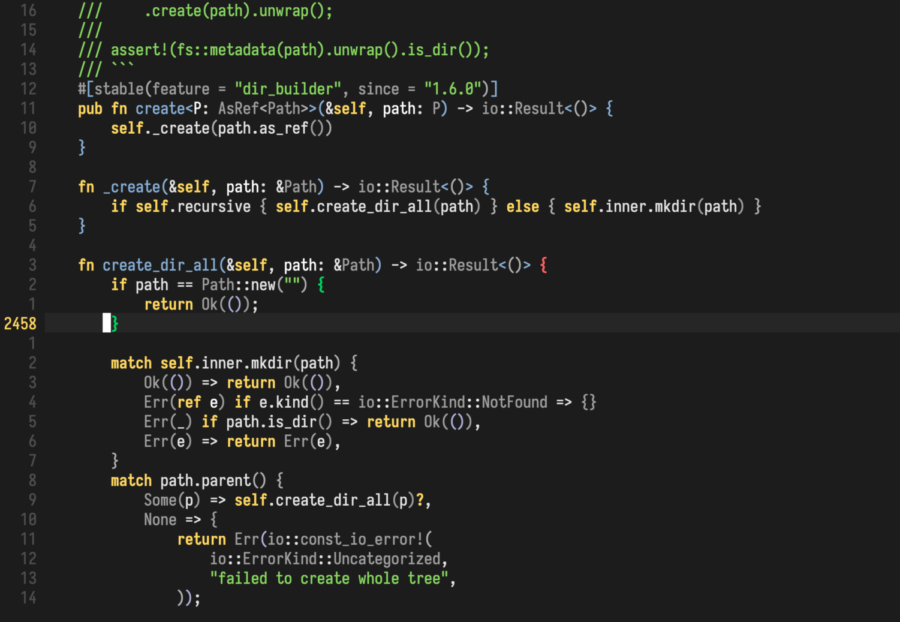

Backend logic, often written in languages like Python or JavaScript, is employed to automate the assignment of part numbers to new inventory items. This automation ensures that part numbers are consistently assigned according to predefined ranges, minimizing human error.

Python scripts, for example, can be integrated into inventory systems to automatically allocate part numbers based on predefined rules or ranges, streamlining operations and reducing the risk of misclassification.

Integration with ERP Systems:

Enterprise Resource Planning (ERP) systems, such as SAP, often come with proprietary languages and tools to manage part numbers within specified ranges. These systems are designed to integrate various aspects of production schedules, inventory management, and procurement.

By using PartNumberRanges, ERP systems can automate workflows, ensuring that parts are correctly categorized and processed according to production needs. This seamless integration helps maintain inventory accuracy and facilitates real-time tracking of parts throughout the supply chain.

Read: Jones Financial Plan For Nonprofit Organizations – Nonprofit Finance!

Why PartNumberRanges is Crucial for Kaiserslautern’s Industries?

Supporting Efficient Manufacturing Processes:

In Kaiserslautern, home to several advanced manufacturing and engineering firms, PartNumberRanges plays a crucial role in supporting efficient production workflows. By organizing parts into structured ranges, companies can quickly identify, track, and allocate materials or components to production lines.

This streamlining of processes ensures that the right parts are available at the right time, helping manufacturers meet deadlines and reduce downtime in their operations.

Enhancing Inventory Management:

Kaiserslautern’s industries rely heavily on effective inventory management systems, and PartNumberRanges are essential to this process. With large inventories of various components, PartNumberRanges help in categorizing parts, making it easier for warehouse managers to locate and manage stock.

The use of these ranges simplifies inventory tracking, ensuring that parts are readily available when needed and minimizing the risk of overstocking or stockouts.

Facilitating Automation and Integration:

Many of the city’s industries have embraced automation to improve production efficiency. PartNumberRanges are crucial in this context as they allow for seamless integration between automated systems and the inventory database.

Using algorithms, companies can automate part number assignment, part selection, and stock updates based on predefined ranges, minimizing the need for manual intervention and reducing the potential for errors. This automation also enhances the speed and accuracy of production processes.

Read: Wdroyo Insurance Tcnevs – Unlock the Secrets to Smarter Coverage!

Frequently Asked Questions:

1. How Does PartNumberRanges Prevent Confusion in Manufacturing?

PartNumberRanges prevent confusion by categorizing parts into specific numerical ranges based on characteristics such as type, size, or function. This structured approach ensures that components are easily identifiable, reducing the chances of errors and mismatches in production and inventory management.

2. Can PartNumberRanges Be Customized for Different Industries?

Yes, PartNumberRanges can be customized to meet the specific needs of different industries. For example, automotive manufacturers may use ranges for engine components, while electronics companies may organize parts by functionality. This flexibility makes the system adaptable to a variety of production environments.

3. How Does Automation Enhance the Use of PartNumberRanges?

Automation simplifies the assignment and management of PartNumberRanges by using backend logic in programming languages like Python or JavaScript. Automated systems can allocate part numbers, monitor inventory, and process large datasets efficiently, minimizing human error and speeding up operations.

4. What Challenges Can Be Addressed with PartNumberRanges?

PartNumberRanges helps address challenges like mismanagement of inventory, production delays, and inefficiencies in the supply chain. By creating a structured numbering system, manufacturers can streamline tracking, improve workflow accuracy, and ensure timely availability of critical components.

5. Why Is Kaiserslautern an Ideal Setting for Implementing PartNumberRanges?

Kaiserslautern, with its strong focus on automotive manufacturing and advanced technology industries, provides the perfect environment for implementing PartNumberRanges. The city’s emphasis on innovation and efficiency allows industries to leverage this system to enhance production processes, optimize supply chains, and improve overall productivity.

Conclusion:

PartNumberRanges is a method for organizing parts in manufacturing and inventory systems. It helps companies group parts by specific ranges, making it easier to track and manage them. This system is widely used in Kaiserslautern’s industries, especially in automotive and electronics. By categorizing parts, businesses improve efficiency, reduce errors, and streamline operations.

PartNumberRanges also enhances inventory control and supports better production workflows. Overall, it is a key strategy for improving productivity and quality in manufacturing environments.

Read more: